Secure Data Platform for Diverse Assets

CASE STUDY

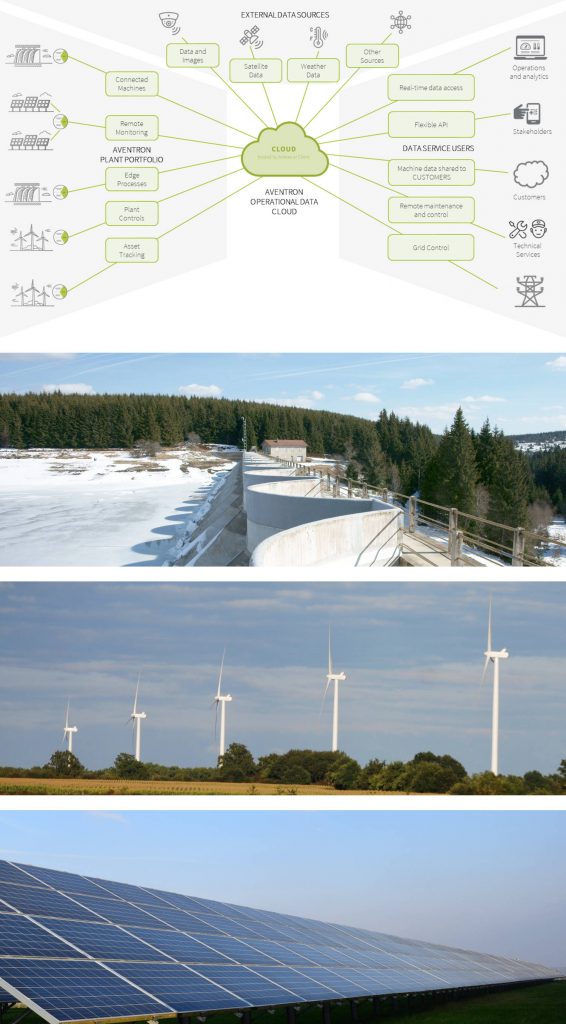

Secure data platform for a diverse portfolio

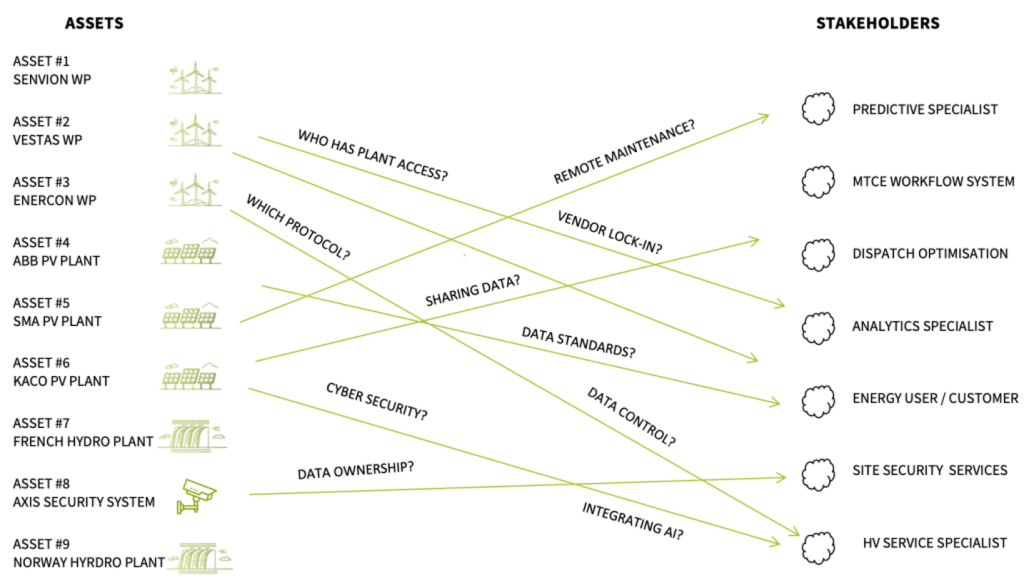

Control of all operational plant data was critical to overcome significant security and operational challenges in managing aventron’s growing asset portfolio.

- Inconsistent visibility of asset performance

- Large diversity of data and plant access standards

- Many different technical operators controlling remote access and data storage

- Limited real-time plant data

- Hundreds of internal and external data users

- High dependance on timely third party reporting

OVERVIEW

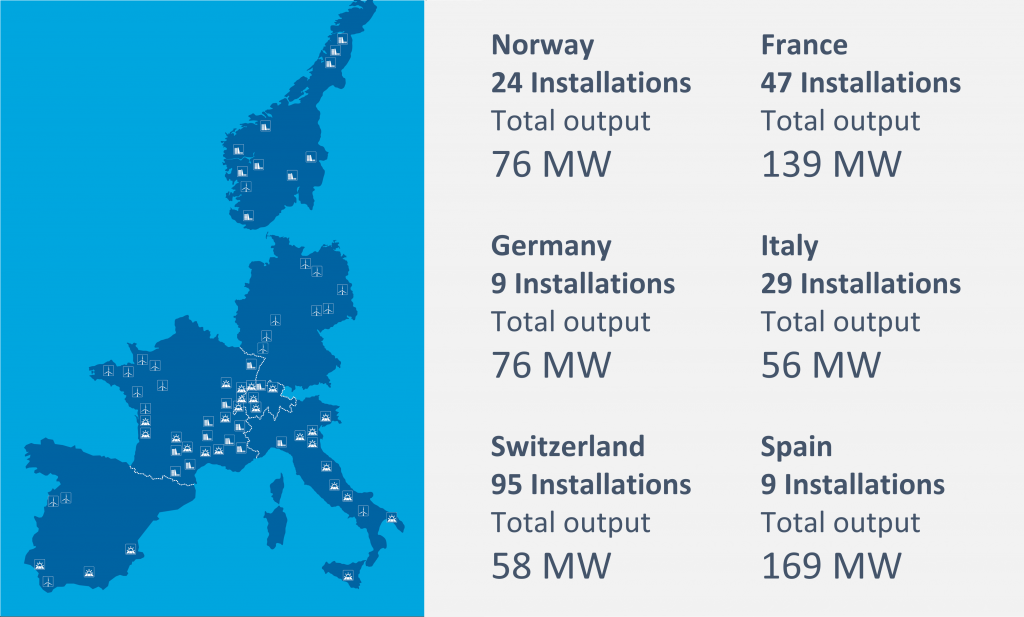

In early 2016, aventron recognized that legacy systems used to manage their plants were not delivering the security and operational data required for effective portfolio operations. The existing operation engaged more than 30 technical operating companies and 200 plant operations resources across a highly diverse range of plant, data formats and access standards. These complexities would only get worse as the aventron portfolio grows.

Given the lack of data control, aventron initiated a program to set data standards and establish direct data connections to every plant.

THE APPROACH

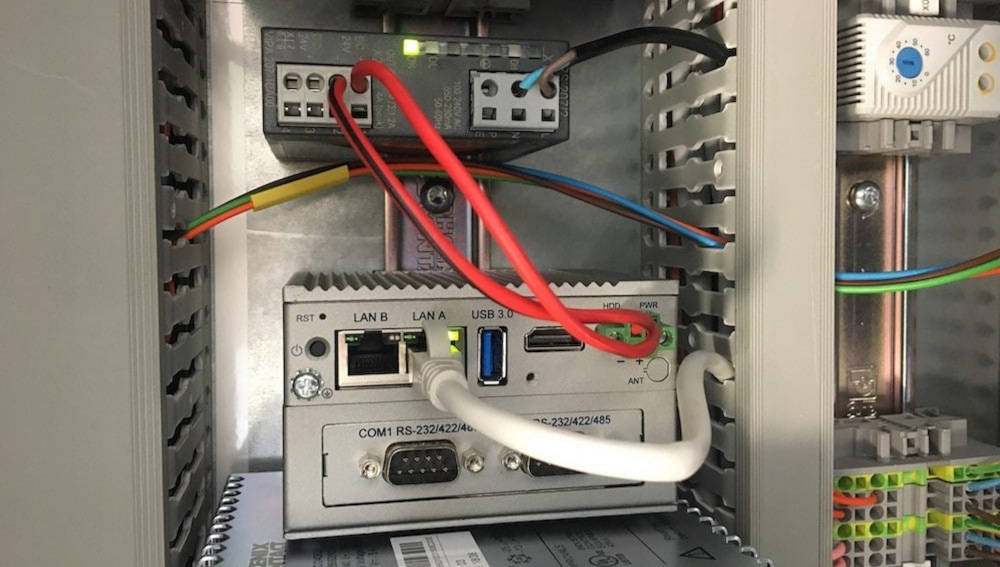

Separate proof of concepts for hydro, solar and wind parks were initiated. An Ardexa edge device installed at each plant established simultaneous machine and cloud connections. Strong collaboration with technical operators ensured all stakeholders were trained and familiar with IT methods.

ABOUT AVENTRON

aventron AG owns and operates a balanced portfolio of renewable power generation assets across Europe. As of 2021 aventron has over 600 MW in installed capacity, comprising 22 wind, 43 hydro plants and more than 100 solar plants. aventron intends to grow its’ portfolio to 1000 MW, and consolidate its position as a leading renewable power operator for Europe.

Within a few months, the proof of concepts were complete and this provided aventron important information to set the standards for full implementation. Over the next 18 months most the 160 plants were connected, and the centralization of aventron plant data in a secure and controlled cloud environment was in place.

BENEFITS

ALL DATA UNDER ONE ROOF

A single aventron cloud connected directly to machines ensures real-time data reliability and consistency. This avoids accessing data from SCADA systems or third-party clouds. The aventron data cloud is now the primary access point for third-parties, with analytical and other specialist companies accessing data via an aventron issued API. aventron has enforced data normalization standards for all machine data. This enables the users to view and analyze data in a consistent manner, irrespective of manufacturer, models and technical operators.

ENHANCED DATA CONTROL AND SECURITY

aventron now controls all data sharing and distribution inside and outside the business. Data cloud access is provided via MFA login or secure API tokens. The Ardexa platform architecture is secure by design and incorporates strong security tools for use by aventron. The platform has allowed aventron to fully close many plant firewalls and protect legacy plant equipment with poor security standards. Upgraded security standards continue to evolve at aventron.

FLEXIBLE OPEN ARCHITECTURE

Legacy plants have traditionally accepted closed standards which limit the asset owner’s ability, at a portfolio level, to bring together a large diversity of machine types and brands. Adoption of an open architecture model, including edge hardware selection, use of Linux and open source plugins gives aventron flexibility to connect any plant, any machine, multi-task devices, reduce costs and switch hardware suppliers in future.

RAPID AND REMOTE DEPLOYMENT

Technical operators were only required to install and connect a pre-configured Ardexa device for each plant. Ardexa completed all implementation and data mapping remotely utilizing Ardexa remote working tools. This meant a faster and more cost effective deployment for the portfolio.

A FUTURE FORWARD MODEL

Every year additional plants are connected with ease. aventron has now also incorporated plant control, including grid connections and plant production limits. This was done using controllers and PLCs running on the same edge device, reducing implementation costs and complexity.

“We have the ambition to adopt advances in modern data acquisition, Internet of Things and narrow AI solutions to enhance our productivity. Ardexa has helped us understand the possibilities and choose a cost-effective way forward”.

aventron CEO